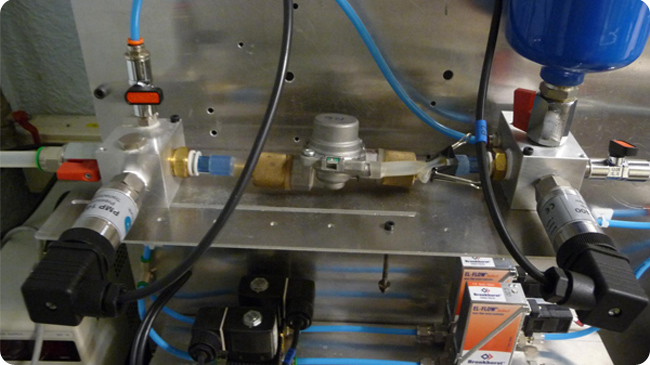

Test bench for control valves

- Home

- Success stories

- Test bench for control valves

The development of the test system and of the product at the same time allows early detection of faults of the system increasing the reliability of the first prototypes."

Other success stories

The development of a testing system for gas control valves, based on Labview. Monitoring of pressures, flows, pressure drops and valve performance when changes occur in environmental conditions. Generation of statistical data based on the testing of a large number of valves..

Copreci manufactures different components for gas stoves. One of these components is a control valve for REMOTION systems (http://www.copreci.com/remotion/index_emotion.htm). This valve makes it possible to vary the gas flow. In order to develop a new version, a new test bench was needed that would make it possible to precisely measure the valve performance, with a degree of accuracy greater than 1 mbar.

Solution provided

A complete turnkey system was developed based on client specifications:

- Stainless steel and aluminum mechanical housing.

- Precision test system with electronic regulation, solenoid valves, flow gauges, etc.

- Control cabinet with CompactDAQ data acquisition system (http://www.ni.com/dataacquisition/compactdaq/).

- Control program based on Labview. Enables us to perform different tests, configure them and analyze the data obtained. It is possible to export results to Excel.

Advantages

- Delivery of a complete turnkey system, according to client specifications.

- Configurable system that will permit testing new models from the same line that are developed in the future.

- User-friendly interface, thanks to Labview programming.

- The use of standard formats for data storage facilitates their subsequent analysis and use.