Fatigue testing system for a piezo igniter.

- Home

- Success stories

- Fatigue testing system for a piezo igniter.

National Instruments hardware and Labview software allowed the acquisition and displaying of ultra high speed signals, something unthinkable some years ago.”

Other success stories

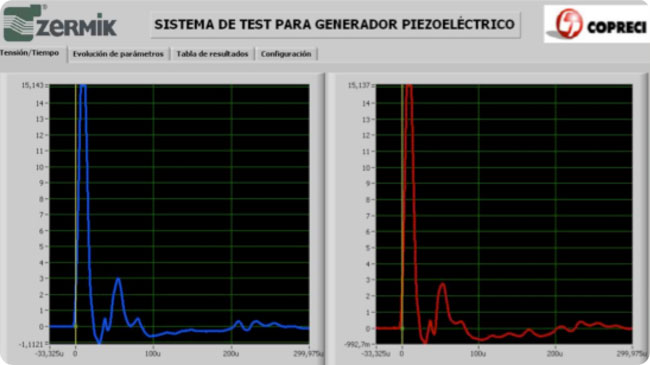

Copreci manufactures different components for gas stoves. One of these components is a piezo igniter. It consists of a mechanical system which, when a piezoelectric material is struck, creates a spark to light the flame. Copreci wanted to measure the quality of the spark produced and monitor the fatigue of the piezoelectric material in tests with several thousand cycles.

The measurement of the voltage generated first required an adaptation, due to its high voltage (around 25 kV). Very high speed sampling was also called for, since the overall duration of the spark is only a few microseconds.

Solution provided

A compact machine was developed capable of alternately turning the lighter back and forth, so that it generated two sparks. The resulting voltage was transferred to an attenuator to convert 25Kv into 1V.

An NI USB6525 card was used for motor control and limit switches. An NI -PCI5105 card with a acquisition frequency of 60 MHz was chosen for data acquisition.

A system control program was developed with Labview. The test can be customized and the acceptance criteria set for the piezoelectric igniter. The program can save the results of each spark in Excel format, which may later be used to create graphs or customized reports.

Advantages

- The National Instruments hardware permits acquisition frequencies of up to 60MHz, making it possible to view the development of the spark in a very precise manner.

- Labview programming made it possible to shorten development times and implement a user-friendly interface.

- The use of standard formats for data storage facilitates their subsequent analysis and use.