Development of a new electronic controller based on a microcontroller.

- Home

- Success stories

- Development of a new electronic controller based on a microcontroller.

Lavbiew FPGA allowed to validate the control algorithm in an early stage of the project, improving lead time.”

Other success stories

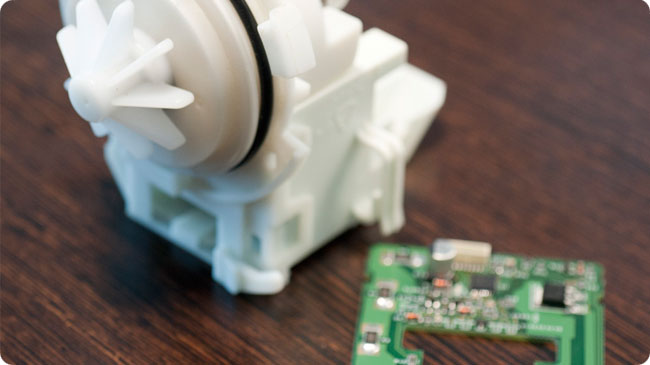

Copreci’s goal was to develop a new control system for one of its products. Only the theoretical development of the control system was available, the product of a previous research Project, but it had never been tested on a real product. The goal was to go from a theoretical concept to a product capable of being industrialized.

Solution provided

Starting with the client’s original idea, a system was developed that was programmed in Labview and based on a card with FPGA that permitted10 nanosecond control loops. This system was used to validate the proposed technique, and a series of parameters were optimized to improve control..

Once the first phase was completed, a control card was designed based on a PIC microcontroller. The control algorithm was adapted for use by the microcontroller and a pre-series of 25 units were manufactured for demonstration and reliability testing. During a later phase, the hardware design will be optimized to permit the industrial implementation of the system.

Advantages

- The development of the first functional prototype based on Labview and FPGA makes it possible to reach the required control loop speed with a PC-based system that is easy to program and modify. It was possible to validate the feasibility of the idea within a short period of time, and quickly improve the control algorithm.

- The construction of a pre-series with a microcontroller makes it possible to demonstrate the product to potential clients and to conduct reliability tests (fatigue cycles, environmental chamber tests, EMC tests, etc.).

- The developmental process was streamlined, with Copreci contributing their knowledge of the system and ZERMIK carrying out the entire process, from validation to assembly. Using only Copreci’s own developmental resources, the developmental period would have been longer, due to their heavy workload on other projects.