Rapid development of functional prototypes.

- Home

- Success stories

- Rapid development of functional prototypes.

In Zermik we optimize the development to adapt to our customer’s requirements. In this project a fast lead time has been reached due to the use of Labview and commercial elements.”

SAIOLAN was studying the feasibility of a business idea for a client. As part of the study, it was necessary to analyze the user response to the new product in question. This made it necessary to manufacture 5 prototypes within a very short time frame and at a controlled cost.

Solution provided

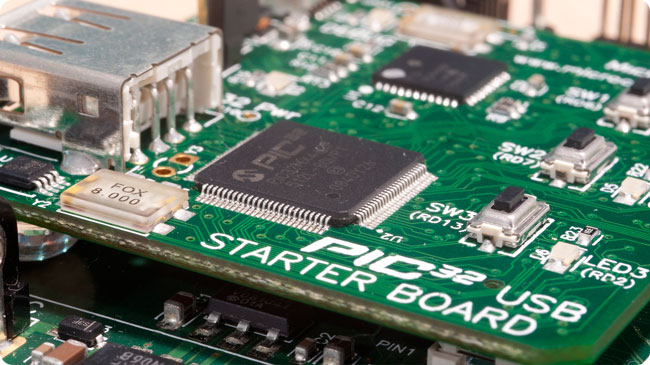

To keep costs down and shorten delivery times, the decision was made to minimize hardware development. Industrial PC and PCI microcontroller development boards were used, manually building the boards to adapt the motor and sensor control system. Based on client specifications, the following tasks were performed:

- System design, using commercially-available components as much as possible. Includes a PC with a touch screen, a development board for Microchip PIC microcontrollers, step-by-step motor control, etc.

- Design of a new photoelectric sensor.

- Integration of the necessary components, adapting the voltage levels by means of manually built boards.

- System programming, using Labview and C.

- Start-up and delivery of 5 prototypes for evaluation.

Advantages

- The development time was shortened by using standard hardware and building the necessary adapters by hand. The prototype behaves exactly like the final product, as far as the user is concerned.